Aluminum HYLUG™ Terminal and HYLINK™ Splice Connectors

®

®

® LISTED WIRE CONNECTOR

® LISTED WIRE CONNECTOR

TYPES YA-A and YS-A

90°C, up to 35 kV

RECOMMENDED FOR USE ON COPPER AND ALUMINUM CONDUCTOR

INSTALLATION INSTRUCTIONS:

| 1 |

|

Use a HYLUG™ terminal or HYLINK™ splice

marked for the wire size to be used.

Never use a copper crimp connector on aluminum wire. |

| 2 |

|

Strip the wire insulation without nicking

or ringing the conductor strands |

| 3 |

|

Always wire brush the stripped portion

of the conductor to remove oxide film. |

| 4 |

|

Insert the conductor all the way into the barrel and crimp the

connector using a die index number and color marked

on the connector. Be sure orientation is correct before crimping. |

| 5 |

|

Wire brush any unplated surface to which the HYLUG™

will be attached and coat the contact surface

with PENETROX™ joint compound

Remove any excess PENETROX™ before taping. |

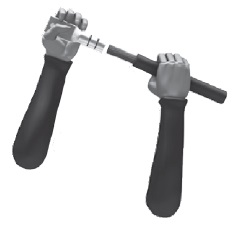

Dieless tools and nest/indenter tools will have a completed crimp similar to illustration shown BELOW:

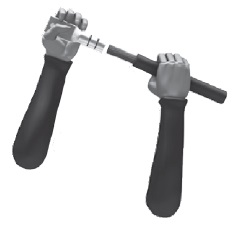

Other die sets listed have a completed crimp of a more circumferential nature and will look similar to this illustration:

®

®  ® LISTED WIRE CONNECTOR

® LISTED WIRE CONNECTOR